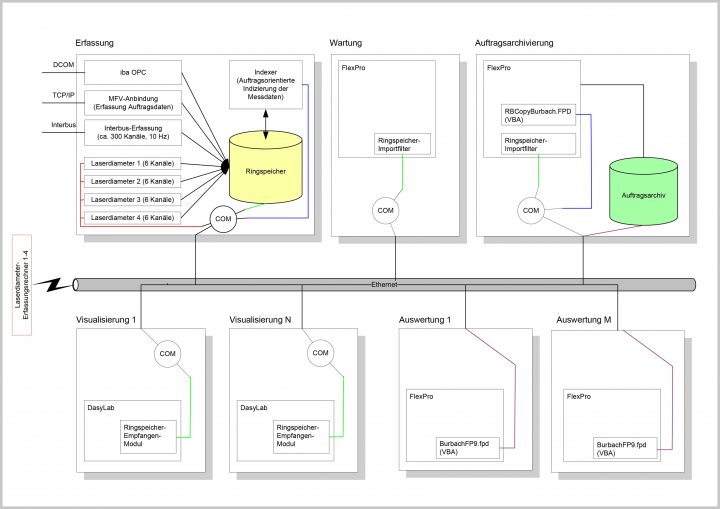

Weisang implemented a system for the high-performance wire rod mill (capacity: 1,000,000 metric tons/year) to capture, analyze and store its data.

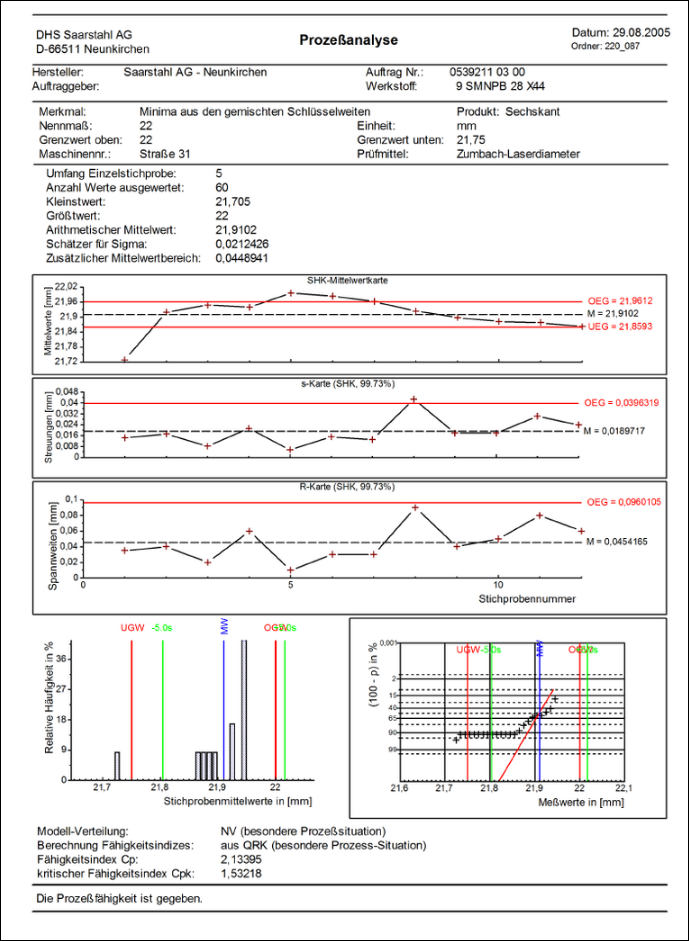

The mill has a single strand at the entry point (annealing furnace) and splits twice along the way, ending up with four strands. The rolling mill produces wire rod material (5 to 15 mm in diameter) around the clock. The raw material (billet) is run through a blooming mill to end up with the required dimensions as it moves along the mill path, is measured by laser diameter gauge at the end and is then placed on a cooling line in the shape of coils. After cooling, the material is bundled and stored as coils.

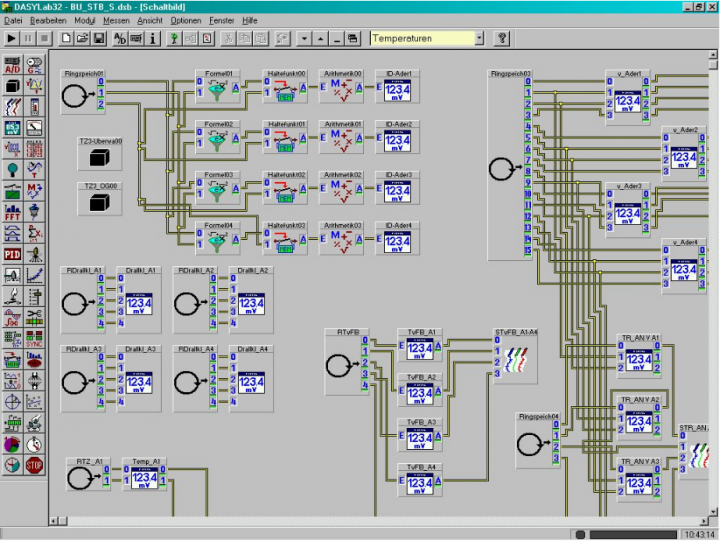

The system has a material flow tracker (MFT) which, combined with photodiodes and temperature cameras, makes order-based tracking of the billets through the entire system possible. Signals for temperature, water consumption, water pressure, speed and other factors are recorded continuously along the mill path.

At process-relevant points in the system, which spans several hundred meters, there are control stations with personnel who use data measured at their location to manually control the system, regulate the mill process or even stop the system in the event of a malfunction.