Standard software masters complex railway operation simulations

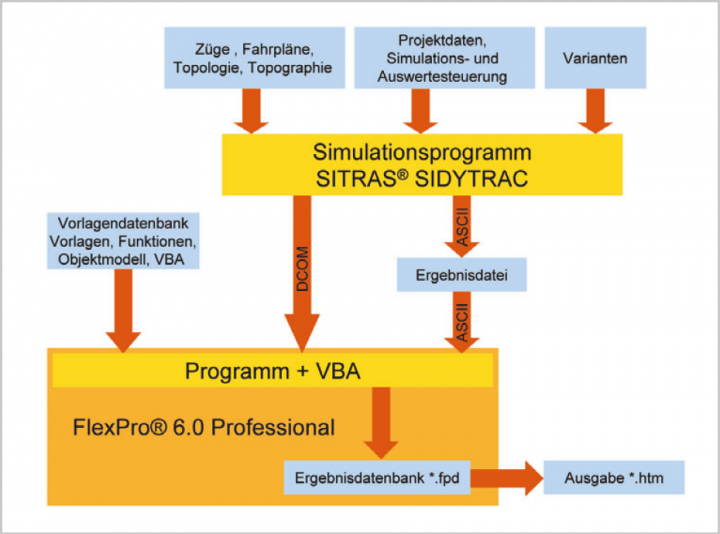

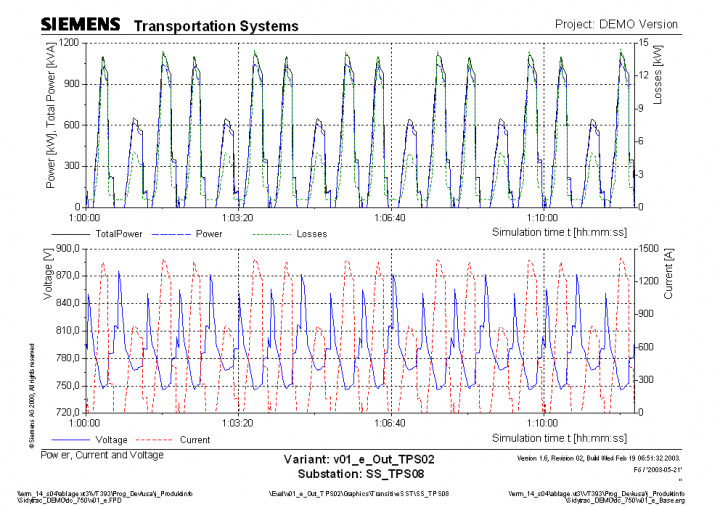

Simulations produce large volumes of data. The goal was to work out the right parameters from the variety of data in order to design traction power networks. Using standard software for measurement analysis made it possible to fulfill these requirements and allowed the simulation software developers to focus on their core task.

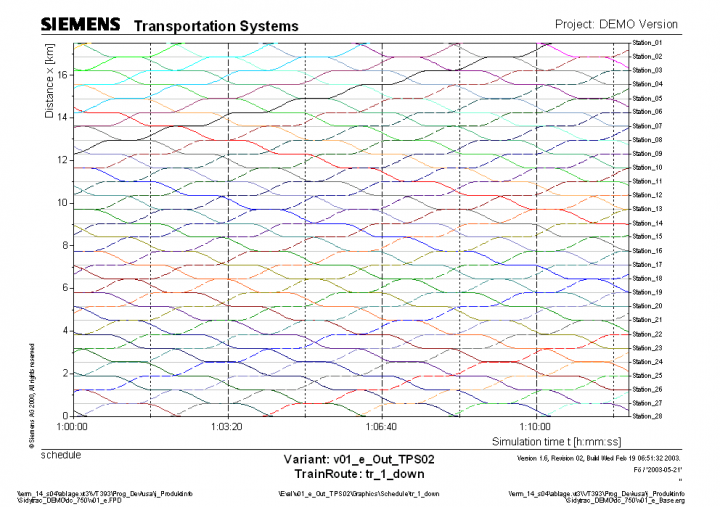

Designing traction power networks using normal calculations is very difficult to do. The interaction between the large number of components is very complicated. Simulations were used to avoid excessive overdimensioning. In the simulation trains can run according to a timetable. For this purpose they require electrical power input or they return the electrical power during braking. The required electricity flows across the power supply network.