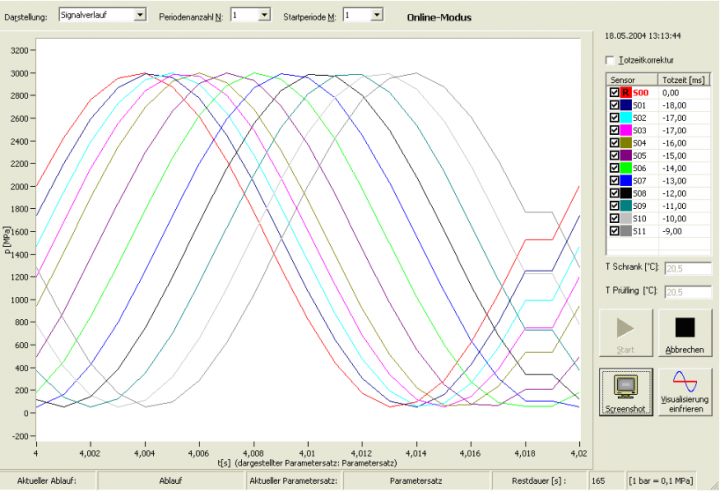

The test bench is used as a reference sensor for automated measuring of high-precision pressure sensors while pressure, pressure type, frequency and temperature are altered.

The key components of the test bench are a conditioning cabinet in which up to 10 units under test and the reference sensor can be mounted on a rail, and a hydraulic system for dynamic pressure generation that is controlled and regulated using a PLC. These components were manufactured and supplied by FMB-Blickle.

A Yokogawa WE7000 data acquisition system was used to collect the data at a sampling rate of up to 100 KHz and to set the curve for the pressure progression.

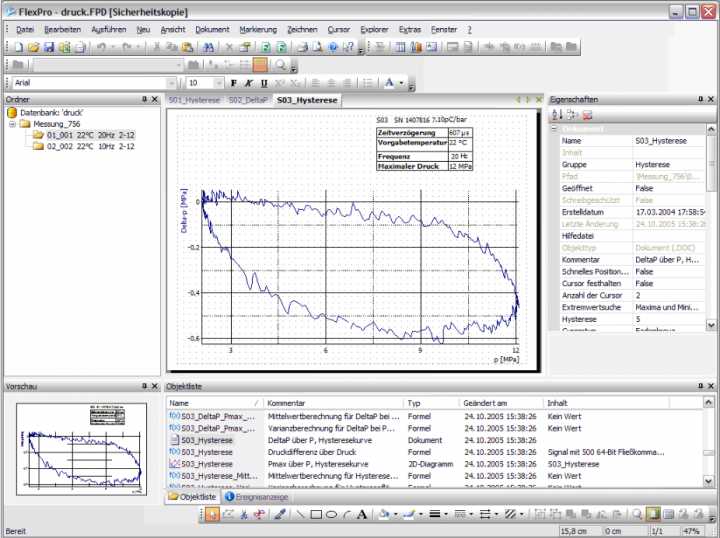

The two software components for operating the test bench and analyzing the test data were developed by Weisang. The HistoryBase ring buffer database was used for data management and as an interface between the data acquisition and analysis components. The analysis was done using FlexPro.